For a long time, it seemed like the scenario applied more to the distant future. But it has become harsh reality much sooner than expected. All over the world, certain PCB components and raw materials are becoming scarcer all the time. This is having an enormous impact on buyers of PCBA in the IoT industry.

The challenge

First let’s return to the problem: the availability of more and more EMS components is coming under increasing pressure. Why is that happening? There are four main reasons for it:

1. The demand for PCB components is increasing.

As a PCBA designer, you know this better than anyone: the number of IoT applications is growing every day. And so is the need for the components and raw materials used to manufacture them.

2. Many PCB component suppliers have streamlined their catalogues.

There has been a major allocation of production, so there are fewer producers left. Moreover, these producers have discontinued a number of less regular and less successful products.

3. More and more raw materials are becoming scarcer.

Initially, this seemed to be incidental, but the figures are looking bleaker all the time. For example, the availability of copper has decreased significantly since manufacturers started producing electric cars on a larger scale.

4. Due to miniaturization, any larger components are being phased out.

The industry will be working more and more with smaller components, so the production of larger components is becoming less attractive. PCBA design is becoming more important.

This leads to two different results.

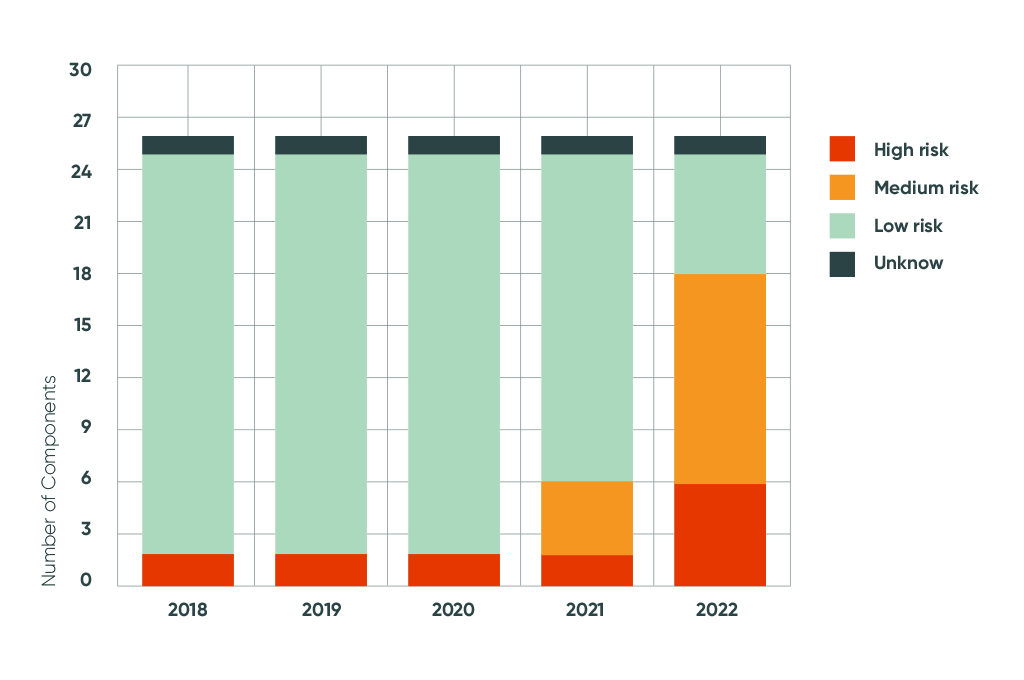

On the one hand, there is increasing uncertainty about the future availability of larger and less common PCBA components. And that is obviously affecting your products. So you need to know:

- Which smart components will still be available for my products in the long run?

- Which smart components are being phased out?

- And… what are the alternatives? (Also when a component is withdrawn from the market without warning, which has been known to happen…)

On the other hand, we’re seeing a substantial increase in the prices of these products. That too requires a smart approach.