The world of EMS development is facing a serious problem: we have noticed that certain components and raw materials are becoming increasingly scarce. And that’s not just a problem for buyers. Read why IoT engineers need to be vigilant even during the design phase.

The challenge

One of the main reasons for the limited availability of many components is the miniaturization of products. Quite simply, smaller products need smaller parts and therefore smaller components. And as an IoT product designer you know this better than anyone.

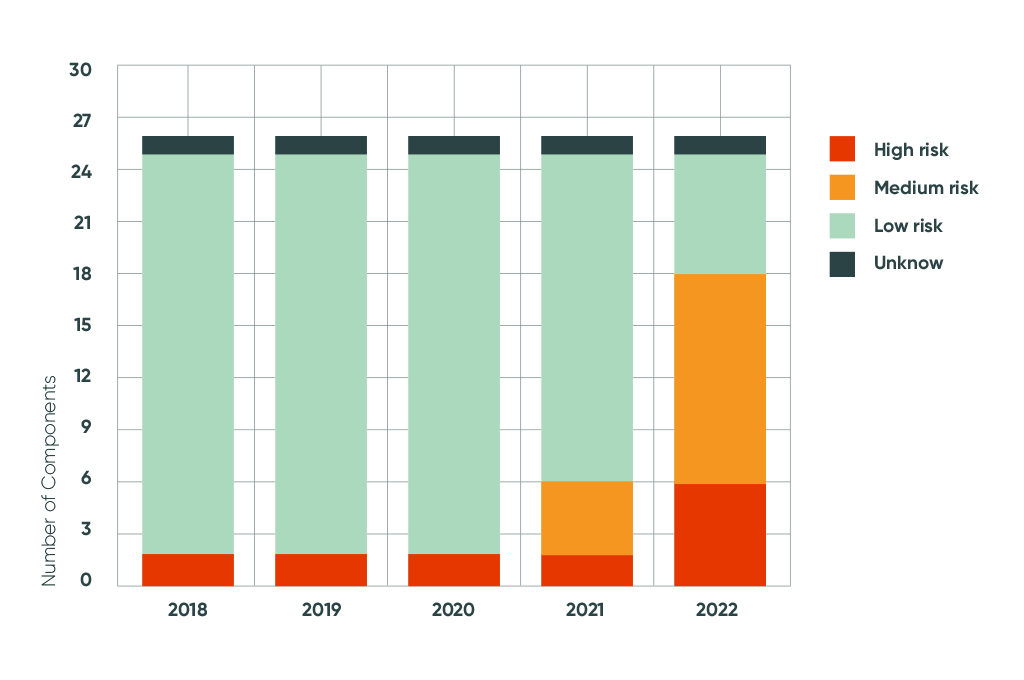

The result: a discrepancy between supply and demand.

Moreover, many component suppliers have discontinued their less common and less successful products, resulting in even more shortages. Then there is the fact that the supply of some resources is dwindling (such as copper, especially since we started producing electric cars on a larger scale).

Due to industry 4.0 a growing number of electronic products and electronic components are added to that list, it’s obvious that a growing number of components are becoming increasingly hard to come by.

The impact of electronic products development on industrial IoT producers is twofold:

1. Growing uncertainty

After all, you want to know at an early stage which components will still be available over the long term and what alternatives will be available. (Also if a component is withdrawn from the market without warning, which has been known to happen.)

2. Substantial increase in the prices of these products

This is primarily the concern of the buyers, of course. Until they have to tell the designers that certain components are becoming too expensive and can no longer be used.