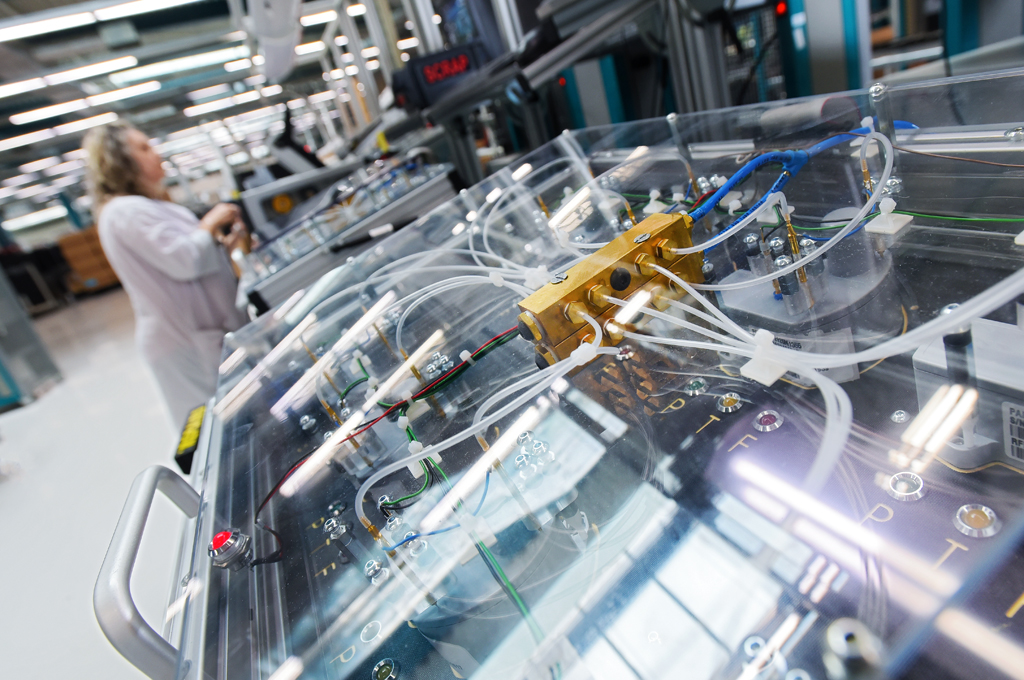

Many manufacturers of mechanical products are making their products smart by switching to electronic drives. One of the key success factors in this process is often overlooked: the need for testing.

Here’s why this is so important.

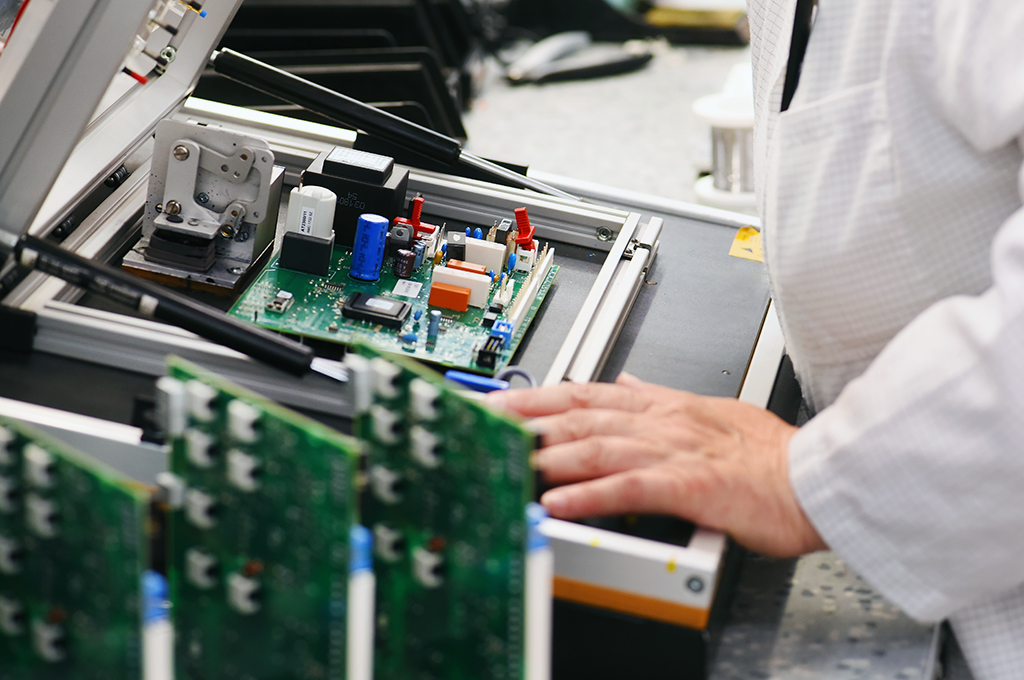

Manufacturers usually have no trouble producing the first few – smaller – batches. But when the time comes to switch to larger-scale production, they often face unexpected challenges. In fact, those challenges mostly turn out to be key success factors. Testing may be the most important of them, as lead time, expenses and – your responsibility – quality fail to meet expectations without testing PCBs properly.

More data, fewer errors

Testing is even more important for electronic products than for their mechanical counterparts. From soldering quality up to and including component mixing: all these aspects contribute to the lead time, costs and quality of both the product and the production process.

Why? Because testing PCBs reduces the probability of defective products and – by extension – the number of return shipments.

However, since it also leads to valuable data and insights that can help to improve both the product and the production process, we at Semecs endorse the use of both Design for Manufacturing (DfM) and Design for Testing (DfT). During this stage, we will review together how the PCB can be designed in such a way as to optimize it for testing.

Needless to say, it’s not our role to second-guess the product designer. The challenge is to come up with the most effective solution together.